The beginnings

Mannheim-Rheinau

In the 1870s, when the chemical industry moved into the area to form the basis for the Mannheim factory of today, the name “Rheinau,” with its overtones of “pastures by the Rhine,” was rather deceptive. It was actually an area of fallow land, almost completely unpopulated, surrounding an abandoned parade ground approximately 8 kilometers south of the royal seat of Mannheim. It was exactly the right place to establish the “Rheinau Chemical Factory” in 1873, as the company was intending to manufacture soda, using the Leblanc process, and potash – a process that was impossible to do without the expulsion of toxic vapors.

The factory had a railroad connection very early on. In addition, its own dock on the nearby Rhine was put into service in 1897. As the Leblanc process for manufacturing soda was unable to compete with the Solvay process, that had gained momentum after 1873, production had to be halted at the Chemische Fabrik Rheinau in 1884. After a thorough renovation, the Aachen company Chemische Fabrik Rhenania took over the factory in 1887. The Rheinau plant was then modernized for the first time, and the manufacture of hydrochloric acid and its by-products in particular was of considerable importance for a long period. In the 1890s, production was expanded to include sulfur, nitric acid, chlorinated lime and sodium sulfate.

In 1912 Rhenania offered the factory, which by then employed around 320 workers, to Th. Goldschmidt AG, a newly founded company looking for a secure supply of initial components and heavy chemicals.

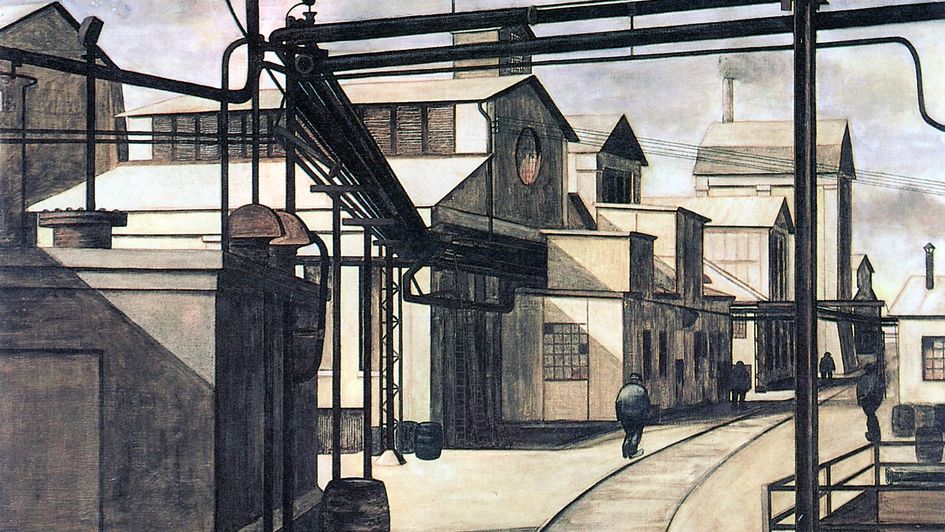

Th. Goldschmidt AG factory in Mannheim, Bergin plant, oil painting

Takeover by Goldschmidt

After the takeover and incorporation by Goldschmidt in 1912, it had been intended to thoroughly modernize and expand the Mannheim-Rheinau factory. However, the outbreak of the war in 1914 made it impossible to fully realize these plans; only a large new factory for the manufacture of sulfuric acid was completed. In 1916, Rheinau was selected as the site for an experimental plant planned by Friedrich Bergius for the hydrogenation of coal - the manufacture of gasoline from coal. Although the “Bergin plant” produced small quantities of gasoline for the first time in 1918, it never really achieved operational maturity.

In 1919, after the end of WWI, Goldschmidt invested in the production of zinc chloride. 1928 saw the pioneering production of “Prodorit,” a bituminous building preservative. The Prodorit line was a great success that continued into the 1960s. In the 1920s and 1930s, new plants for manufacturing barium, barium chloride, and blanc-fixed - barium sulfate - were built. However, WWII prevented thorough renovation of the site.

As the individual installations at the Rheinau factory were hardly damaged during the war, it was possible to resume production very soon after 1945. Unlike the parent factory in Essen, which was completely destroyed, there was no need to build any new, significantly rationalized facilities. The company made do with isolated measures, such as modernizing the sulfuric acid factory and the sulfur operation in the mid 1950s. Production of chlorinated rubber and color varnishes was also added. Up to 1945 these had been produced in factories in Halle/Saale, which were expropriated after the end of the war.

From the 1960s onwards, the production of inorganic heavy chemicals in Rheinau became increasingly less significant for Th. Goldschmidt AG.

Factory Mannheim-Rheinau, Aerial view, 1971

Nevertheless, the company continued to invest, for example, in a pilot plant in the 1970s and in a new production plant for manufacturing sulfuric acid in the 1980s. Furthermore, all of the metallurgy that remained at Goldschmidt was gradually moved to Rheinau. This included the manufacture of special zinc alloys and magnetic materials. The site was sold off in 2008 and there are, after 100 years, no longer any relations to today’s Evonik Goldschmidt GmbH.