From fertilizers to construction chemicals

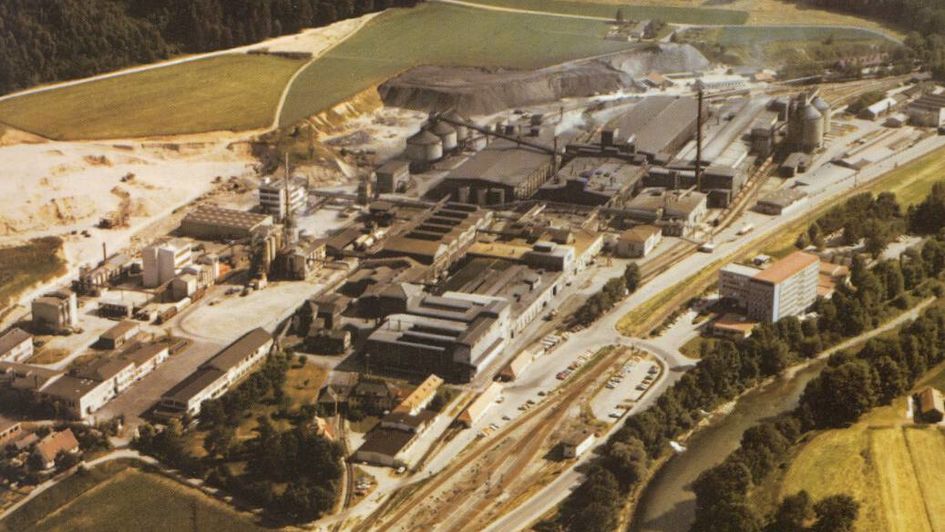

Trostberg

The founding of the site

The Bayerische Stickstoffwerke AG (Bavarian Nitrogen) was founded in Munich on November 6, 1908. This was the starting point for today’s Evonik site in Trostberg, in northern Chiemgau, Germany. It was decided to set up the works in Trostberg because Cyanidgesellschaft mbh in Berlin, the parent company of Stickstoffwerke AG, wanted to use the Alz, a tributary of the River Inn, to generate electricity. This was a crucial consideration as manufacturing fertilizer from calcium cyanamide is a very energy intensive process. Up to then, the Alz had regularly flooded the area, making it necessary to alter its course. By 1912, as part of this operation, two hydroelectric power stations were built in Trostberg and Schalchen to supply the power for the plant. The Alz was particularly suitable for electricity generation as it has the steepest gradient of any river in Germany and can therefore generate abundant hydropower.

War time boom

The Trostberg plant was soon producing large quantities of calcium cyanamide and was, in fact, the first factory in Germany to make it on an industrial scale. In 1913, Bayerische Stickstoffwerke AG produced 20,000 tons and during the First World War, annual output was projected to 225,000 tons. As a result, the site was expanded in the years 1915-19, creating an additional plant. In 1923, Bayerische Stickstoffwerke, with its Trostberg site, merged with VIAG (Vereinigte Industrie-Unternehmungen Aktiengesellschaft - Associated Industrial Enterprises AG), a newly-founded company owned by the Reich. In the following years, the company continued to expand the calcium cyanamide plant in Trostberg until the end of the 1920s, when it was brought down by the global economic crisis and hyperinflation and suffered huge falls in production and sales.

The years under National Socialism

When the National Socialists came into power in 1933, the downswing ended. The economic revival was the result of National Socialist striving for autarchy, economic self-sufficiency, in which increasing agricultural output played a significant role. As a result, the demand for calcium cyanamide as a fertilizer was high in order to increase “the yield of the German soil,” a strategy pursued at the time. In 1939 Bayerische Stickstoffwerke AG and Bayerische Kraftwerke AG (Bavarian power company) merged to become Süddeutsche Kalkstickstoff-Werke AG [Southern German Calcium Cyanamide Works] (SKW) with its headquarters in Trostberg. During the war, the buildings and equipment in Trostberg were spared from the bombing for a long time, until February 22, 1945, just a few weeks before the war ended. An aerial mine hit the factory in a daytime raid, the first and only one at that location. The mine came down on the company health insurance fund building. Sixteen people died in the underground shelter.

Reconstruction

After the end of the war in May 1945, the SKW Board was removed by US authorities, the management was suspended and the company handed over to trustees. Calcium cyanamide production restarted in December 1945. The site and the whole of SKW remained under US control until in 1949 it was transferred to the Bavarian State Office for Asset Management and Reconstruction.

A new Board of Directors and a new Board of Management were appointed for SKW. Modernization of the site in Trostberg already began in 1948 in the course of which new equipment was put into operation to produce guanidine. Guanidine is the raw material from which artificial resin, medicine and dyes are produced. New administration buildings and a new canteen were built later on.

In the 1950s, the first rotary furnace was put into operation in Trostberg. This was used in the manufacture of granulated calcium cyanamide (PERLKA), an important advance on traditional fertilizers. In the years that followed, this product enjoyed such success that eight more production furnaces were installed at the site.

Moving into NCN chemistry

For the time being, agriculture remained the most important target for production in Trostberg, with calcium cyanamide the key product. However, an important step towards broadening the product range was taken in 1948 with the development of NCN chemistry. NCN chemistry is the name given to products containing typical nitrogen-carbon-nitrogen compounds. A whole palette of these products was developed in Trostberg. MELAMIN, dicyanodiamide and guanamine are all examples of this kind of product. They are used as source materials for laminates or molded compounds and for water vapor impervious adhesives and finishes. Initially, these organic by-products were manufactured in a pilot plant in Trostberg. Production was then moved to a disused carbide factory in Schalchen. In 1968, another product range was introduced when SKW started to manufacture MELMENT, a concrete plasticizer which is also part of NCN chemistry. MELMENT and its variants formed the basis for SKW Construction Chemicals, a development which secured the company its position as a global market leader.

In 1978 the company’s name changed from Süddeutsche Kalkstickstoff-Werke AG to SKW Trostberg AG. Its headquarters remained in Trostberg. Another production branch was created in 1980 when experiments to extract natural substances started in Trostberg. This eventually became the Nature Products division in 1987. In 1990 the experimental and production sections of this division were brought together in the newly-built Nature Products pilot plant (NATEC) in Trostberg.

After the merger of SKW Trostberg AG with Degussa-Hüls in February 2001, Construction Chemicals were sold off to BASF in 2006. The remaining chemical activities were run by the subsidiary AlzChem GmbH. Late in 2009, AlzChem was sold off to financial investor BluO. The still resident companies are forming the “Chemiepark Trostberg”, which could celebrate its centenary in 2008 under the label “100 years chemical works in Trostberg”